Installation and Welding

PVC membranes are delivered to the job site in rolls or prefabricated panels, the size of which is determined by the shape and size of the structure. Seams are produced either by hot air or hot wedge welding, depending on the type of seam specified. The welding equipment can be adjusted to allow for temperature and humidity conditions on the site.

Generally, the sheets are loosely laid and do not require the substrate to be dry. This can be the deciding factor in choosing the type of waterproofing in areas where there is continuous water seepage through the rock or where open-cut construction exposes the lining to weather for long periods of time.

The leveling layer, composed of a non-woven geotextile mat or drainage fabric, is an indispensable element in the waterproofing system.

All materials used in the system, including concrete, must be compatible to ensure that the material properties of age resistance, elongation, and tensile strength will last for years.

Welding Methods

Hot Wedge Welding

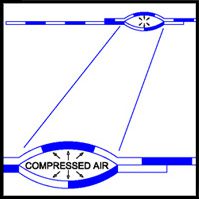

For use with polyethylene and PVC waterproofing membranes to produce long straight seams. The membranes are overlapped and the wedge is inserted between the sheets. The heated surfaces are pressed between wheels above and below to produce a strong double weld with a space between for air pressure testing after the application is complete.

Air Pressure Test

The air pressure test requires that the channel between the two welds be sealed at both ends and inflated to 30 psi (2 bar). Test results are positive when the pressure does not fall more than 5 psi (.33 bar) in 10 minutes. The pressure in the channel stresses the weld providing evidence of its integrity.

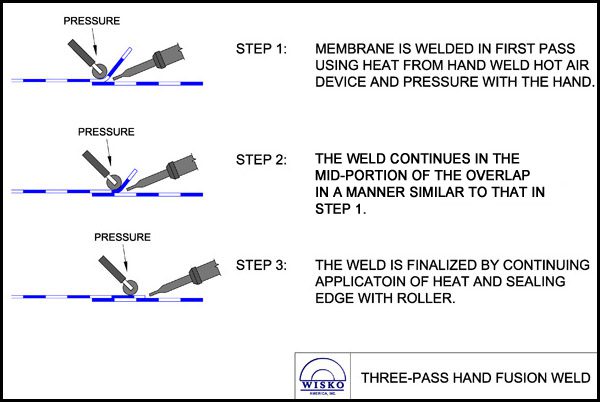

Hot Air Welding

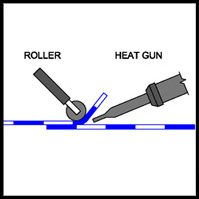

For use with PVC waterproofing membranes. Hot air welding requires controlled heat from a hot air gun be applied between the membranes. The hot surfaces are then pressed together with a roller to complete the weld. The weld is made with three passes with hand-held heat gun . Welds are mechanically tested for continuity.

WISKO America, Inc. field technicians are trained in the installation of membranes other than the PVC referenced in the preceding text. Each underground project should be evaluated to determine which membrane best meets the specific project requirements. Material thickness should also be evaluated when designing an underground waterproofing system. With our many years of project experience, the management of WISKO America, Inc. is available for consultation on your waterproofing requirements.